ENTREPRENEURSHIP

MODEL: PRINTING PROCESSES SIMULATION

WITH TIMES AND PRICES IN THE BASE FOR NORMATIVE PROVISIONS

Vilko Ziljak1, Vladimir Simovic2, Klaudio Pap1

1University of Zagreb, Croatia, Faculty of Graphic Engineering,

HR-10000, Zagreb, Getaldiceva 2, FS@zg.tel.hr

2University of Zagreb, Croatia, College of Business and Business Administration "Baltazar Adam Krcelic", HR-10290 Zapresic, Vladimira Novaka 23, vladimir.simovic@uazg.hr

Abstract

To make improvement in printing processes production, we create the base for normative provisions, which are described with execution times and prices. Database is relational set which can be edited only in the occasion of "data deep analysis" gained from the real production and simulation experiments. All input output working activities with the digital normative provisions are going throughout the XML native technology. This work shows efficiency of preparing input data for simulation of complex relationships in Pre-Press and Press, with intention to organize sequential experimental simulation design. Experimental results are also organized as the XML native database, with goal of multiple analyses in future. Knowledge’s organized as database is base for planning of printing processes research for all participants in this production. Last researches showing that the biggest unknown is establishment of normative provisions for prices, because former working flows are fulfil with idling. Hard simulation discovers disproportion between real production and its analytical definition. Feedback is correction of all normative provisions that are in usage for calculations. In practice, that is very delighted work because it can cause errors with strong consequences. That is reason why someone has to organize multiple databases and enable simulations with completely different point of views on production.

Keywords: entrepreneurship, normative provisions, XML, stochastic simulation

1 Introduction

Graphical industry is one of the most complex industries today. That is evident according to thousands of various products which are every day around us. These graphical products are results of the huge numbers of combinations between processes and capacities. Consequently, these are the reasons why we are today researching for possibilities of processes automation in this industrial branch. Something is definitely the same as before that the processes of developing a graphical product consist from phases of: graphical preparation, pressing technology, and graphical finishing. In all of these three phases there are the huge numbers of possibilities of executions and mutual chaining of processes. It is necessary to introduce integration and automation in complex systems of graphical industry because of necessity to reduce work execution time and execution more complex works. Two authors at the Faculty of Graphic Engineering in Zagreb (V. Ziljak, PhD, and K. Pap, PhD) and with these premises successfully developed programming model “Webposkok”. With this model it is now possible to create phases of graphical production on various devices and capacities. Only provision for that was to make normative provision description (read possibility) of all production process factors. The whole model was established on normative provision basis, where all operations and capacities were described in detail. The XML (eXtensible Mark-up Language) was recognized as new language of data description and data transferring between applications and systems from various producers (manufacturers or makers). That provides creations of individual solutions in automation of graphical production and possibility of knowledge integration between the normative provisions and standards in graphical industry which came from various sources. Normative provisions database is filling up almost one year and existing data provides complex analysis and conclusion making. In this work researching goal is situation where we have to make decision about optimal selection of one offset machine from the specified machine set for concrete work. In fact we have to decide which of specified editions of concrete work is profitable to execute on one machine, but in relation to other machine. These machines have different characteristics, from velocity parameters to working hour price. It is not clear for which editions to make best (optimal, adequate) machine selection, and it is not always clear even financial aspect of that decision. Goal is to accomplish graphs of execution velocities and of financial profitability analysis of that decision (to make optimal selection of one offset machine from the specified machine set for specified interval editions of concrete work).

2 Normative provisions database with times and prices

Dictionary describing normative provisions of graphical production is relatively large and usually very differential. Process of establishing standardisation in graphical production can be divided into three categories: normative provisions definition for the machinery park (manual works are included), normative provisions definition for the processes and interrelation definition. Normative provisions must be changeable during the whole period of time. It is reachable by exploration of benefits given from XML technology and relational databases technology. These technologies are extension of each other and they don’t exclude each other. Reliable and stable relational database was constructed with MSSQL Server Database and with XML interface throughout XML Scheme, into which requested communication dictionary can be defined and which is not with equal names and definitions of tables into its relational database. On that way different sorts of normative provisions are transforming into unambiguous record which have developed programming modules for production knot processing. Relational database is using as repository for data recording and saving. These data are in relation with all normative provisions, relations and transactions which happened in one period of time. XML Scheme provides us with definition possibilities of look up of XML documents, with establishment of table and field connections into relational database, and with possibilities of relations definition, on the level of XML elements and attributes. Every machine for specific task execution must have some time for preparation and time for production (or execution). Both times usually don't have the same price, but even the same number of people (workers) and capacities. Some machines have different (operational) working modus, which have different time for production (execution). All time parameters about machine preparation and production velocity, together with related prices, are recording into database.

3 Model of pressing machine from sheet feed

We are demonstrating the complexity of specific processing knot description in graphical production on description example of pressing machine which is printing from sheet feed. Normative provisions set of that machine consists from these variables: number of press-drums, time for machine preparation for first form, time for machine preparation for next forms, time for duplex mechanism preparation, time for machine washing, time for exchanging the same set of panels, machine format, printing velocity, machine preparation working hour price, machine working hour price. These prices are in relation with today developments of these machines. Whole machine must be additionally standardized. Printing machines are not often printing with declared velocity. Machines velocities are varying according to specific kind of work, including monitoring of printing quality, and consequently machine velocity must be standardized according to specific kind of work. On figure 1 we are showing XML normative provisions for printing machines. With these normative provisions we are declaring technological additions for of specified editions of work. That is calculation of a technological surplus which has to be included in production, and without which description of printing phase is incomplete, calculations of production time and price are false. Technological additions are dividing on additions related to printing process and additions related to finishing process, which just follows. Both of them work standardizing according to edition intervals, but not according to functional dependences. Printing process addition is different for every machine, but technological addition related to finishing process depends only on type of finishing process and it is independent from printing machine type.

Figure 1 XML normative provisions for printing machines (in Croatian)

Figure 2 Normative provisions for offset panels (in Croatian)

Figure 3 Normative provisions for paper (in Croatian)

Type of offset panel which is used from printing machine has impact on time needed for production (execution) of specific edition. That is reason why we have descriptions of offset panels in our model. Their parameters are: producer, format, price, and endurance (figure 2). If edition on specific panel is above its endurance parameter then we must exchange all panels on whole machine, what has impact on production time and price of work. Printing machine with offset panels spending also paper capacity, which is described by normative provisions into database. Between basic normative provisions for paper variables we have: inventory number, description, gram values, sheet format, and sheet price (figure 3).

4 Model solution with XML technology

Developed XML model represents calculation of time and printing price. Model has all options in production that are needed for accomplishing a specific finished product. That are XML elements as identification name of calculating experiment, ID of printing machine which is prepared for printing, ID of selected paper, ID of selected offset panel, normative provision ponder for velocity of printing, defined edition of work, number of work pages, format of work page, format of printing sheet, number of colours from front and number of colours from opposite side of page, and number of pages on sheet paper. Experimental results are on the same XML document, and analysed model variables have results presented on clear and unique manner. Resulted XML elements which are calculating and recording into XML document are, for example: edition of sheet paper, planed edition of sheet paper with incorporated technological and finishing addition, number of panels, time of machine preparation, time of machine cleaning, time of printing, total needed time for finalisation of product edition, papers costs, panels costs, colours costs, total price of product edition, and product unit price (figure 4).

Figure 4 Resulted XML elements - calculated and recorded into XML document (in Croatian)

5 Experimenting with model

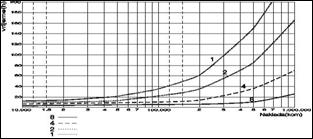

Goal of experimental researching is optimal selection of one offset machine from the specified machine set for concrete work. Experiments were taken on model for work with these variables: leaflet (flyer) A4, 4/4, from B1, 135 grams paper, and colour coverage 50%. All measures were taken for editions from 500 to 1,000,000; and with machines with normative provisions: 1-colour (one press-drum), 2-colours, 4-colours, and 8-colours. Also, eight-colour machine has in process duplex modulo. Conclusion was that region of measuring interest was upper editions from 10,000; because it was clear that under that limit we can’t make optimal decisions. On graph in figure 5 we have measuring results of executing times for printing phases which were accomplished on all four printing machines for specified editions. That was result of 112 experimental model starts, from which 44 were made for selecting an optimal measuring edition interval, and 68 were made for measuring into defined interval borders. Printing machines normative provisions were used in model and (data taken and filled up almost one year from Croatian printing houses) were results of normative provisions mean values. In figure 6 we have unit prices of specific product for all four printing machines according to edition. Product unit price executed on: 1-colour and 2-colour machine has crossing point at 12,000 leaflets, 2-colour and 4-colour at 30,000 edition, 4-colour and 8-colour at 50,000. These crossings are momentums when we have optimal edition intervals for machines which are in relation with unit price of specific work, as we can see (for work: leaflet (flyer) A4, 4/4, from B1, 135 grams paper, colour coverage 50%) next relations: machine type « (edition interval); 1-colour « (0-12,000); 2-colours « (12,000-30,000); 4-colours « (30,000-50,000); 8-colours « (50,000-¥).

Figure 5 Results of execution times for printing phases on 4 printing machines (in Croatian)

Figure 6 Unit prices of specific product for 4 printing machines edition (in Croatian)

6 Conclusion

This model can be used for every work on printing machines. For less then minute we recorded parameters of selected work. For less then one hour we finished our experiments with machines in relation to editions. For given goal function, we have plans to develop programming modulo which will execute all parallel printings and optimums into defined edition ratio and selected work. This work gives effective analysis of a printing process which is complex system. Developed model was based on relational database where all necessary normative provisions and prices are saved, and which have developed XML system with XML Schemes. Process recognition and transformation into adequate form were then connected, what was relatively easy because of existence of a XML description and relational database. Once described capacities, operations and process-production knots in XML language gives possibilities for development of electronic simulators, calculations, working orders, and productions plans in one printing house.

7 References

[1] Pap, K. (2003). Standards During the Whole Printing Process Production (published in Croatian), International symposium "Offset printing", Zagreb.

[2] Pap, K. (2003). Standardisation and Automation of Graphic Production in XML (published in Croatian), International symposium "Offset printing", Zagreb.

[3] Ziljak, V. (1982). Simulation with Computer (published in Croatian), School Book, Zagreb.